Mobile electronics are becoming more accessible and widespread every year, if not month. Here you will find laptops, PDAs, digital cameras, mobile phones, and a host of other useful and not so useful devices. And all these devices are constantly acquiring new features, more powerful processors, larger color screens, wireless communications, while at the same time decreasing in size. But, unlike semiconductor technologies, power technologies for this entire mobile menagerie are not progressing by leaps and bounds.

Conventional batteries and rechargeable batteries are becoming clearly insufficient to power the latest advances in the electronics industry for any significant period of time. And without reliable and capacious batteries, the whole point of mobility and wirelessness is lost. So the computer industry is working more and more actively on the problem alternative sources nutrition. And the most promising direction here today is fuel cells.

The basic operating principle of fuel cells was discovered by British scientist Sir William Grove in 1839. He is known as the father of the "fuel cell". William Grove generated electricity by altering to extract hydrogen and oxygen. Having disconnected the battery from the electrolytic cell, Grove was surprised to find that the electrodes began to absorb the released gas and generate current. Opening a process electrochemical "cold" combustion of hydrogen became a significant event in the energy industry, and subsequently such famous electrochemists as Ostwald and Nernst played a major role in the development of the theoretical foundations and practical implementation of fuel cells and predicted a great future for them.

Myself term "fuel cell" appeared later - it was proposed in 1889 by Ludwig Mond and Charles Langer, who were trying to create a device for generating electricity from air and coal gas.

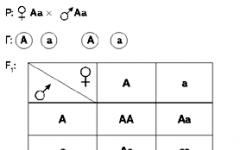

During normal combustion in oxygen, oxidation of organic fuel occurs, and the chemical energy of the fuel is inefficiently converted into thermal energy. But it turned out to be possible to carry out the oxidation reaction, for example, of hydrogen with oxygen, in an electrolyte environment and, in the presence of electrodes, obtain electricity. For example, by supplying hydrogen to an electrode located in an alkaline medium, we obtain electrons:

2H2 + 4OH- → 4H2O + 4e-

which, passing through the external circuit, arrive at the opposite electrode, to which oxygen flows and where the reaction takes place: 4e- + O2 + 2H2O → 4OH-

It can be seen that the resulting reaction 2H2 + O2 → H2O is the same as during conventional combustion, but in a fuel cell, or otherwise - in electrochemical generator, the result is electric current with great efficiency and partially heat. Note that coal, carbon monoxide, alcohols, hydrazine, and others can also be used as fuel in fuel cells. organic matter, and as oxidizing agents - air, hydrogen peroxide, chlorine, bromine, Nitric acid etc.

The development of fuel cells continued vigorously both abroad and in Russia, and then in the USSR. Among the scientists who made a great contribution to the study of fuel cells, we note V. Jaco, P. Yablochkov, F. Bacon, E. Bauer, E. Justi, K. Cordesh. In the middle of the last century, a new assault on fuel cell problems began. This is partly due to the emergence of new ideas, materials and technologies as a result of defense research.

One of the scientists who made a major step in the development of fuel cells was P. M. Spiridonov. Hydrogen-oxygen elements of Spiridonov gave a current density of 30 mA/cm2, which was considered a great achievement at that time. In the forties, O. Davtyan created an installation for the electrochemical combustion of generator gas obtained by gasification of coal. For each cubic meter of element volume, Davtyan received 5 kW of power.

It was first solid electrolyte fuel cell. It had high efficiency, but over time the electrolyte became unusable and needed to be changed. Subsequently, Davtyan, in the late fifties, created a powerful installation that drives the tractor. In the same years, the English engineer T. Bacon designed and built a battery of fuel cells with a total power of 6 kW and an efficiency of 80%, running on pure hydrogen and oxygen, but the power-to-weight ratio of the battery turned out to be too small - such elements were unsuitable for practical application and too expensive.

In subsequent years, the time for loners passed. The creators of spacecraft became interested in fuel cells. Since the mid-60s, millions of dollars have been invested in fuel cell research. The work of thousands of scientists and engineers allowed us to reach a new level, and in 1965. fuel cells were tested in the USA on the Gemini 5 spacecraft, and later on the Apollo spacecraft for flights to the Moon and the Shuttle program.

In the USSR, fuel cells were developed at NPO Kvant, also for use in space. In those years, new materials had already appeared - solid polymer electrolytes based on ion exchange membranes, new types of catalysts, electrodes. Still, the operating current density was small - in the range of 100-200 mA/cm2, and the platinum content on the electrodes was several g/cm2. There were many problems related to durability, stability, and safety.

The next stage of rapid development of fuel cells began in the 90s. last century and continues to this day. It is caused by the need for new efficient energy sources in connection, on the one hand, with the global environmental problem of increasing greenhouse gas emissions from the combustion of fossil fuels and, on the other hand, with the depletion of reserves of such fuel. Since in a fuel cell the final product of hydrogen combustion is water, they are considered the cleanest in terms of environmental impact. The main problem is just finding an effective and inexpensive way obtaining hydrogen.

Billions of dollars in financial investments in the development of fuel cells and hydrogen generators should lead to a technological breakthrough and make their use in everyday life a reality: in cells for cell phones, in cars, in power plants. Already, such automobile giants as Ballard, Honda, Daimler Chrysler, and General Motors are demonstrating cars and buses powered by fuel cells with a power of 50 kW. A number of companies have developed demonstration power plants using fuel cells with solid oxide electrolyte with a power of up to 500 kW. But, despite a significant breakthrough in improving the characteristics of fuel cells, many problems related to their cost, reliability, and safety still need to be solved.

In a fuel cell, unlike batteries and accumulators, both fuel and oxidizer are supplied to it from the outside. The fuel cell only mediates the reaction and, under ideal conditions, could operate virtually forever. The beauty of this technology is that the cell actually burns fuel and directly converts the released energy into electricity. When fuel is directly burned, it is oxidized by oxygen, and the heat released is used to perform useful work.

In a fuel cell, as in batteries, the reactions of fuel oxidation and oxygen reduction are spatially separated, and the “combustion” process occurs only if the cell supplies current to the load. It's just like diesel electric generator, only without diesel and generator. And also without smoke, noise, overheating and with much higher efficiency. The latter is explained by the fact that, firstly, there are no intermediate mechanical devices and, secondly, the fuel cell is not a heat engine and, as a result, does not obey Carnot’s law (that is, its efficiency is not determined by the temperature difference).

Oxygen is used as an oxidizing agent in fuel cells. Moreover, since there is enough oxygen in the air, there is no need to worry about supplying an oxidizing agent. As for fuel, it is hydrogen. So, the reaction takes place in the fuel cell:

2H2 + O2 → 2H2O + electricity + heat.

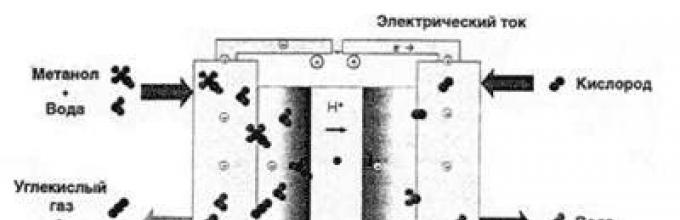

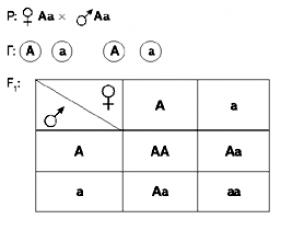

The result is useful energy and water vapor. The simplest in its structure is proton exchange membrane fuel cell(see Figure 1). It works as follows: hydrogen entering the element is decomposed under the action of a catalyst into electrons and positively charged hydrogen ions H+. Then a special membrane comes into play, playing the role of an electrolyte in a conventional battery. Due to its chemical composition it allows protons to pass through but retains electrons. Thus, the electrons accumulated on the anode create an excess negative charge, and the hydrogen ions create a positive charge on the cathode (the voltage across the element is about 1V).

To create high power, a fuel cell is assembled from many cells. If you connect an element to a load, electrons will flow through it to the cathode, creating a current and completing the process of oxidation of hydrogen with oxygen. Platinum microparticles deposited on carbon fiber are usually used as a catalyst in such fuel cells. Due to its structure, such a catalyst allows gas and electricity to pass through well. The membrane is usually made from the sulfur-containing polymer Nafion. The thickness of the membrane is tenths of a millimeter. During the reaction, of course, heat is also released, but not so much of it, so the operating temperature is maintained in the region of 40-80°C.

Fig.1. Operating principle of a fuel cell

There are other types of fuel cells, mainly differing in the type of electrolyte used. Almost all of them require hydrogen as fuel, so the logical question arises: where to get it. Of course, it would be possible to use compressed hydrogen from cylinders, but problems immediately arise associated with the transportation and storage of this highly flammable gas under high pressure. Of course, hydrogen can be used in bound form, as in metal hydride batteries. But the task of extracting and transporting it still remains, because the infrastructure for hydrogen refueling does not exist.

However, there is also a solution here - liquid hydrocarbon fuel can be used as a source of hydrogen. For example, ethyl or methyl alcohol. True, this requires a special additional device - a fuel converter, which at high temperatures (for methanol it will be about 240 ° C) converts alcohols into a mixture of gaseous H2 and CO2. But in this case, it is already more difficult to think about portability - such devices are good to use as stationary devices, but for compact mobile equipment you need something less bulky.

And here we come to exactly the device that almost everyone is developing with terrible force. largest producers electronics - methanol fuel cell(Figure 2).

Fig.2. Operating principle of a methanol fuel cell

The fundamental difference between hydrogen and methanol fuel cells is the catalyst used. The catalyst in a methanol fuel cell allows protons to be removed directly from the alcohol molecule. Thus, the issue with fuel is resolved - methyl alcohol is mass-produced for the chemical industry, it is easy to store and transport, and to charge a methanol fuel cell it is enough to simply replace the fuel cartridge. True, there is one significant disadvantage - methanol is toxic. In addition, the efficiency of a methanol fuel cell is significantly lower than that of a hydrogen one.

Rice. 3. Methanol fuel cell

The most tempting option is to use ethyl alcohol as fuel, since the production and distribution of alcoholic beverages of any composition and strength is well established throughout the globe. However, the efficiency of ethanol fuel cells, unfortunately, is even lower than that of methanol ones.

As has already been noted over many years of development in the field of fuel cells, Various types fuel cells. Fuel cells are classified by electrolyte and fuel type.

1. Solid polymer hydrogen-oxygen electrolyte.

2. Solid polymer methanol fuel cells.

3. Alkaline electrolyte cells.

4. Phosphoric acid fuel cells.

5. Fuel elements based on molten carbonates.

6. Solid oxide fuel cells.

Ideally, the efficiency of fuel cells is very high, but in real conditions there are losses associated with nonequilibrium processes, such as: ohmic losses due to the specific conductivity of the electrolyte and electrodes, activation and concentration polarization, and diffusion losses. As a result, part of the energy generated in fuel cells is converted into heat. The efforts of specialists are aimed at reducing these losses.

The main source of ohmic losses, as well as the reason for the high price of fuel cells, are perfluorinated sulfonic cation exchange membranes. The search is now underway for alternative, cheaper proton-conducting polymers. Since the conductivity of these membranes (solid electrolytes) reaches an acceptable value (10 Ohm/cm) only in the presence of water, the gases supplied to the fuel cell must be additionally humidified in a special device, which also increases the cost of the system. Catalytic gas diffusion electrodes mainly use platinum and some other noble metals, and so far no replacement has been found for them. Although the platinum content in fuel cells is several mg/cm2, for large batteries its amount reaches tens of grams.

When designing fuel cells, much attention is paid to the heat removal system, since at high current densities (up to 1A/cm2) the system self-heats. For cooling, water is used circulating in the fuel cell through special channels, and at low powers - air blowing.

So, a modern electrochemical generator system, in addition to the fuel cell battery itself, is “overgrown” with many auxiliary devices, such as: pumps, a compressor for supplying air, injecting hydrogen, a gas humidifier, a cooling unit, a gas leakage monitoring system, a DC-AC converter, a control processor etc. All this leads to the fact that the cost of a fuel cell system in 2004-2005 was 2-3 thousand $/kW. According to experts, fuel cells will become available for use in transport and stationary power plants at a price of $50-100/kW.

To introduce fuel cells into daily life, along with cheaper components, we must expect new original ideas and approaches. In particular, great hopes are pinned on the use of nanomaterials and nanotechnologies. For example, several companies have recently announced the creation of ultra-efficient catalysts, in particular for oxygen electrodes, based on clusters of nanoparticles from various metals. In addition, there have been reports of membraneless fuel cell designs in which liquid fuel (such as methanol) is fed into the fuel cell along with an oxidizer. Also interesting is the developing concept of biofuel cells operating in polluted waters and consuming dissolved air oxygen as an oxidizer, and organic impurities as fuel.

According to experts, fuel cells will enter the mass market in the coming years. Indeed, one after another, developers overcome technical problems, report successes and present prototypes of fuel cells. For example, Toshiba demonstrated a finished prototype of a methanol fuel cell. It has a size of 22x56x4.5mm and produces a power of about 100mW. One refill of 2 cubes of concentrated (99.5%) methanol is enough for 20 hours of operation of the MP3 player. Toshiba has released a commercial fuel cell to power mobile phones. Again, the same Toshiba demonstrated a cell for powering laptops measuring 275x75x40mm, allowing the computer to operate for 5 hours on a single charge.

Another Japanese company, Fujitsu, is not far behind Toshiba. In 2004, she also introduced an element that operates in a 30% aqueous solution of methanol. This fuel cell operated on one 300 ml charge for 10 hours and produced a power of 15 W.

Casio is developing a fuel cell in which methanol is first converted into a mixture of H2 and CO2 gases in a miniature fuel converter, and then fed into the fuel cell. During the demonstration, the Casio prototype powered a laptop for 20 hours.

Samsung also made its mark in the field of fuel cells - in 2004, it demonstrated its 12 W prototype designed to power a laptop. In general, Samsung plans to use fuel cells primarily in fourth-generation smartphones.

It must be said that Japanese companies generally took a very thorough approach to the development of fuel cells. Back in 2003, companies such as Canon, Casio, Fujitsu, Hitachi, Sanyo, Sharp, Sony and Toshiba joined forces to develop a single fuel cell standard for laptops, mobile phones, PDAs and other electronic devices. American companies, of which there are also many in this market, mostly work under contracts with the military and develop fuel cells for the electrification of American soldiers.

The Germans are not far behind - the Smart Fuel Cell company sells fuel cells to power a mobile office. The device is called Smart Fuel Cell C25, has dimensions of 150x112x65mm and can deliver up to 140 watt-hours per fill. This is enough to power the laptop for approximately 7 hours. Then the cartridge can be replaced and you can continue working. The size of the methanol cartridge is 99x63x27 mm, and it weighs 150g. The system itself weighs 1.1 kg, so it cannot be called completely portable, but it is still a completely complete and convenient device. The company is also developing a fuel module to power professional video cameras.

In general, fuel cells have almost entered the mobile electronics market. Manufacturers still have to solve the last technical problems before starting mass production.

First, it is necessary to resolve the issue of miniaturization of fuel cells. After all, the smaller the fuel cell, the less power it can produce - so new catalysts and electrodes are constantly being developed that make it possible to maximize the working surface with small sizes. This is where the latest developments in the field of nanotechnology and nanomaterials (for example, nanotubes) come in very handy. Again, to miniaturize the piping of elements (fuel and water pumps, cooling and fuel conversion systems), achievements of microelectromechanics are increasingly being used.

The second important problem that needs to be addressed is price. After all, very expensive platinum is used as a catalyst in most fuel cells. Again, some of the manufacturers are trying to make the most of already well-established silicon technologies.

As for other areas of use of fuel cells, fuel cells have already become quite firmly established there, although they have not yet become mainstream either in the energy sector or in transport. Already, many car manufacturers have presented their concept cars powered by fuel cells. Fuel cell buses are running in several cities around the world. Canadian Ballard Power Systems produces a range of stationary generators with a capacity from 1 to 250 kW. At the same time, kilowatt generators are designed to immediately supply one apartment with electricity, heat and hot water.

The US has several initiatives aimed at developing hydrogen fuel cells, infrastructure and technology to make fuel cell vehicles practical and fuel efficient by 2020. More than one billion dollars have been allocated for these purposes.

Fuel cells generate electricity quietly and efficiently, without pollution environment. Unlike energy sources that use fossil fuels, the byproducts of fuel cells are heat and water. How it works?

In this article we will briefly look at each of the existing fuel technologies today, as well as talk about the design and operation of fuel cells, and compare them with other forms of energy production. We'll also discuss some of the obstacles researchers face in making fuel cells practical and affordable for consumers.

Fuel cells are electrochemical energy conversion devices. A fuel cell converts chemicals, hydrogen and oxygen, into water, generating electricity in the process.

Another electrochemical device that we are all very familiar with is the battery. The battery has everything you need chemical elements inside itself and turns these substances into electricity. This means that the battery eventually dies and you either throw it away or charge it again.

In a fuel cell, chemicals are continually fed into it so that it never “dies.” Electricity will be generated as long as chemicals enter the element. Most fuel cells in use today use hydrogen and oxygen.

Hydrogen is the most common element in our Galaxy. However, hydrogen practically does not exist on Earth in its elemental form. Engineers and scientists must extract pure hydrogen from hydrogen compounds, including fossil fuels or water. To extract hydrogen from these compounds, you need to expend energy in the form of heat or electricity.

Invention of fuel cells

Sir William Grove invented the first fuel cell in 1839. Grove knew that water could be split into hydrogen and oxygen by passing an electric current through it (a process called electrolysis). He suggested that in reverse order it would be possible to obtain electricity and water. He created a primitive fuel cell and called it gas galvanic battery. After experimenting with his new invention, Grove proved his hypothesis. Fifty years later, scientists Ludwig Mond and Charles Langer coined the term fuel cells when trying to build a practical model for generating electricity.

The fuel cell will compete with many other energy conversion devices, including gas turbines in urban power plants, internal combustion engines in cars, and all kinds of batteries. Internal combustion engines, like gas turbines, burn different types of fuel and use the pressure created by the expansion of gases to perform mechanical work. Batteries convert chemical energy into electrical energy when needed. Fuel cells must perform these tasks more efficiently.

The fuel cell provides DC (direct current) voltage which can be used to power electric motors, lights and other electrical appliances.

There are several different types of fuel cells, each using different chemical processes. Fuel cells are usually classified according to their operating temperature And typeelectrolyte, which they use. Some types of fuel cells are well suited for use in stationary power plants. Others may be useful for small portable devices or for powering cars. The main types of fuel cells include:

Polymer exchange membrane fuel cell (PEMFC)

PEMFC is considered as the most likely candidate for transport applications. PEMFC has both high power and relatively low operating temperature (ranging from 60 to 80 degrees Celsius). Low operating temperatures mean fuel cells can quickly warm up to begin generating electricity.

Solid oxide fuel cell (SOFC)

These fuel cells are most suitable for large stationary power generators that could power factories or cities. This type of fuel cell operates at very high temperatures (700 to 1000 degrees Celsius). High temperature poses a reliability problem because some fuel cells can fail after a few on-off cycles. However, solid oxide fuel cells are very stable during continuous operation. In fact, SOFCs have demonstrated the longest operating life of any fuel cell under certain conditions. The high temperature also has the advantage that the steam produced by the fuel cells can be sent to turbines and generate more electricity. This process is called cogeneration of heat and electricity and improves overall system efficiency.

Alkaline fuel cell (AFC)

It is one of the oldest designs for fuel cells, having been in use since the 1960s. AFCs are very susceptible to contamination as they require pure hydrogen and oxygen. In addition, they are very expensive, so this type of fuel cell is unlikely to be put into mass production.

Molten-carbonate fuel cell (MCFC)

Like SOFCs, these fuel cells are also best suited for large stationary power plants and generators. They operate at 600 degrees Celsius so they can generate steam, which in turn can be used to generate even more energy. They have a lower operating temperature than solid oxide fuel cells, which means they do not require such heat-resistant materials. This makes them a little cheaper.

Phosphoric-acid fuel cell (PAFC)

Phosphoric acid fuel cell has potential for use in small stationary power systems. It operates at a higher temperature than a polymer exchange membrane fuel cell, so it takes longer to warm up, making it unsuitable for use in automobiles.

Direct methanol fuel cell (DMFC)

Methanol fuel cells are comparable to PEMFC in terms of operating temperature, but are not as efficient. In addition, DMFCs require quite large quantity platinum acts as a catalyst, which makes these fuel cells expensive.

Fuel cell with polymer exchange membrane

Polymer exchange membrane fuel cell (PEMFC) is one of the most promising fuel cell technologies. PEMFC uses one of the simplest reactions of any fuel cell. Let's look at what it consists of.

1. A node – negative terminal of the fuel cell. It conducts electrons that are released from hydrogen molecules, after which they can be used in an external circuit. It has engraved channels through which hydrogen gas is distributed evenly over the surface of the catalyst.

2.TO athode - the positive terminal of the fuel cell also has channels for distributing oxygen over the surface of the catalyst. It also conducts electrons back from the catalyst's external circuit, where they can combine with hydrogen and oxygen ions to form water.

3.Electrolyte-proton exchange membrane. This is a specially treated material that conducts only positively charged ions and blocks electrons. With PEMFC, the membrane must be hydrated in order to function properly and remain stable.

4. Catalyst is a special material that promotes the reaction of oxygen and hydrogen. It is typically made from platinum nanoparticles applied very thinly to carbon paper or fabric. The catalyst has a surface structure such that maximum surface area of the platinum can be exposed to hydrogen or oxygen.

The figure shows hydrogen gas (H2) entering the fuel cell under pressure from the anode side. When an H2 molecule comes into contact with platinum on the catalyst, it splits into two H+ ions and two electrons. The electrons pass through the anode, where they are used in external circuitry (doing useful work, such as turning a motor), and return to the cathode side of the fuel cell.

Meanwhile, on the cathode side of the fuel cell, oxygen (O2) from the air passes through the catalyst where it forms two oxygen atoms. Each of these atoms has a strong negative charge. This negative charge attracts two H+ ions across the membrane, where they combine with an oxygen atom and two electrons coming from the external circuit to form a water molecule (H2O).

This reaction in a single fuel cell produces only about 0.7 Volts. To raise the voltage to a reasonable level, many individual fuel cells must be combined to form a fuel cell stack. Bipolar plates are used to connect one fuel cell to another and undergo oxidation to reduce potential. The big problem with bipolar plates is their stability. Metal bipolar plates can be corroded, and by-products (iron and chromium ions) reduce the efficiency of the fuel cell membranes and electrodes. Therefore, low temperature fuel cells use light metals, graphite and composites of carbon and thermoset (thermoset is a kind of plastic that remains solid even when exposed to high temperatures) in the form of bipolar sheet material.

Fuel cell efficiency

Reducing pollution is one of the main goals of a fuel cell. By comparing a car powered by a fuel cell to a car powered by a gasoline engine and a car powered by a battery, you can see how fuel cells could improve the efficiency of cars.

Since all three types of cars have many of the same components, we will ignore this part of the car and compare useful actions to the point where mechanical energy is produced. Let's start with the fuel cell car.

If the fuel cell is powered by pure hydrogen, its efficiency can be up to 80 percent. Thus, it converts 80 percent of the energy content of hydrogen into electricity. However, we still have to convert electrical energy into mechanical work. This is achieved by an electric motor and an inverter. The efficiency of the motor + inverter is also approximately 80 percent. This gives an overall efficiency of approximately 80*80/100=64 percent. Honda's FCX concept vehicle reportedly has 60 percent energy efficiency.

If the fuel source is not in the form of pure hydrogen, then the vehicle will also need a reformer. Reformers convert hydrocarbon or alcohol fuels into hydrogen. They generate heat and produce CO and CO2 in addition to hydrogen. They use various devices to purify the resulting hydrogen, but this purification is insufficient and reduces the efficiency of the fuel cell. Therefore, the researchers decided to concentrate on fuel cells for Vehicle, running on pure hydrogen, despite the challenges associated with hydrogen production and storage.

Efficiency of a gasoline engine and a battery-electric car

The efficiency of a car powered by gasoline is surprisingly low. All heat that is exhausted or absorbed by the radiator is wasted energy. The engine also uses a lot of power to drive the various pumps, fans and generators that keep it running. Thus, the overall efficiency of a gasoline automobile engine is approximately 20 percent. Thus, only about 20 percent of gasoline's thermal energy content is converted into mechanical work.

A battery-powered electric vehicle has fairly high efficiency. The battery is approximately 90 percent efficient (most batteries generate some heat or require heating), and the motor + inverter is approximately 80 percent efficient. This gives an overall efficiency of approximately 72 percent.

But that's not all. In order for an electric car to move, electricity must first be generated somewhere. If it was a power plant that used a fossil fuel combustion process (rather than nuclear, hydroelectric, solar or wind power), then only approximately 40 percent of the fuel consumed by the power plant was converted into electricity. Plus, the process of charging a car requires converting alternating current (AC) power to direct current (DC) power. This process has an efficiency of approximately 90 percent.

Now, if we look at the whole cycle, the efficiency of an electric vehicle is 72 percent for the vehicle itself, 40 percent for the power plant, and 90 percent for charging the vehicle. This gives an overall efficiency of 26 percent. Overall efficiency varies significantly depending on which power plant is used to charge the battery. If the car's electricity is generated by a hydroelectric power plant, for example, the electric car's efficiency will be approximately 65 percent.

Scientists are researching and improving designs to continue improving the efficiency of the fuel cell. One new approach would be to combine fuel cell and battery-powered vehicles. A concept vehicle powered by a hybrid powertrain powered by a fuel cell is being developed. It uses a lithium battery to power the car while the fuel cell recharges the battery.

Fuel cell vehicles are potentially as efficient as a battery-powered car that is charged from a power plant that does not use fossil fuels. But achieving this potential in a practical and accessible way can be difficult.

Why use fuel cells?

The main reason is everything related to oil. America must import nearly 60 percent of its oil. By 2025, imports are expected to rise to 68%. Americans use two-thirds of oil daily for transportation. Even if every car on the street were a hybrid car, by 2025 the US would still need to use the same amount of oil that Americans consumed in 2000. In fact, America consumes a quarter of all the oil produced in the world, although only 4.6% of the world's population lives here.

Experts expect oil prices to continue rising over the next few decades as cheaper sources dwindle. Oil companies must develop oil fields in increasingly difficult conditions, which will increase oil prices.

Concerns extend far beyond economic security. A lot of money coming from oil sales is spent on supporting international terrorism, radical political parties, unstable situation in oil-producing regions.

The use of oil and other fossil fuels for energy produces pollution. It is best for everyone to find an alternative to burning fossil fuels for energy.

Fuel cells are an attractive alternative to oil dependence. Instead of polluting, fuel cells produce clean water as a by-product. While engineers have temporarily focused on producing hydrogen from various fossil sources such as gasoline or natural gas, renewable, environmentally friendly ways to produce hydrogen in the future are being explored. The most promising, naturally, will be the process of producing hydrogen from water

Dependence on oil and global warming- an international problem. Several countries are jointly involved in promoting research and development for fuel cell technology.

It is clear that scientists and manufacturers have a lot of work to do before fuel cells become an alternative to modern methods of energy production. Yet, with worldwide support and global cooperation, a viable fuel cell power system could become a reality within just a couple of decades.

A fuel cell is an electrochemical energy conversion device that converts hydrogen and oxygen into electricity through a chemical reaction. As a result of this process, water is formed and a large amount of heat is released. A fuel cell is very similar to a battery that can be charged and then use the stored electrical energy.

William R. Grove is considered the inventor of the fuel cell, who invented it back in 1839. In this fuel cell, a solution of sulfuric acid was used as an electrolyte, and hydrogen was used as a fuel, which was combined with oxygen in an oxidizing agent. It should be noted that until recently, fuel cells were used only in laboratories and on spacecraft.

In the future, fuel cells will be able to compete with many other energy conversion systems (including gas turbines in power plants), internal combustion engines in cars and electric batteries in portable devices. Internal combustion engines burn fuel and use the pressure created by the expansion of combustion gases to perform mechanical work. Batteries store electrical energy, then convert it into chemical energy, which can be converted back into electrical energy if necessary. Fuel cells are potentially very efficient. Back in 1824, the French scientist Carnot proved that the compression-expansion cycles of an internal combustion engine cannot provide an efficiency of conversion of thermal energy (which is the chemical energy of burning fuel) into mechanical energy above 50%. A fuel cell has no moving parts (at least not within the cell itself) and therefore they do not obey Carnot's law. Naturally, they will have greater than 50% efficiency and are especially effective at low loads. Thus, fuel cell vehicles are poised to become (and have already proven to be) more fuel efficient than conventional vehicles in real-world driving conditions.

The fuel cell produces a constant voltage electric current that can be used to drive the electric motor, lighting, and other electrical systems in the vehicle. There are several types of fuel cells, differing in the chemical processes used. Fuel cells are usually classified by the type of electrolyte they use. Some types of fuel cells are promising for power plant propulsion, while others may be useful for small portable devices or for powering cars.

The alkaline fuel cell is one of the very first cells developed. They have been used in the US space program since the 1960s. Such fuel cells are very susceptible to contamination and therefore require very pure hydrogen and oxygen. They are also very expensive, so this type of fuel cell will likely not see widespread use in automobiles.

Fuel cells based on phosphoric acid can find application in low-power stationary installations. They operate at fairly high temperatures and therefore take a long time to warm up, which also makes them ineffective for use in cars.

Solid oxide fuel cells are better suited for large stationary power generators that could supply power to factories or communities. This type of fuel cell operates at very high temperatures (around 1000 °C). The high operating temperature creates certain problems, but on the other hand there is an advantage - the steam produced by the fuel cell can be sent to turbines to generate more electricity. Overall, this improves the overall efficiency of the system.

One of the most promising systems is the proton exchange membrane fuel cell (PEMFC - Protone Exchange Membrane Fuel Cell). Currently, this type of fuel cell is the most promising because it can power cars, buses and other vehicles.

Chemical processes in a fuel cell

Fuel cells use an electrochemical process to combine hydrogen with oxygen obtained from the air. Like batteries, fuel cells use electrodes (solid electrical conductors) located in an electrolyte (electrically conductive medium). When hydrogen molecules come into contact with the negative electrode (anode), the latter are separated into protons and electrons. Protons pass through a proton exchange membrane (POEM) to the positive electrode (cathode) of the fuel cell, producing electricity. A chemical combination of hydrogen and oxygen molecules occurs to form water as a byproduct of this reaction. The only kind emissions from the fuel cell - water vapor.

The electricity produced by fuel cells can be used in a vehicle's electric powertrain (consisting of an electrical power converter and an AC induction motor) to provide mechanical energy to propel the vehicle. The job of a power converter is to convert the direct electrical current produced by the fuel cells into alternating current, on which the vehicle's traction motor operates.

Diagram of a fuel cell with a proton exchange membrane:

1 - anode;

2 - proton exchange membrane (PEM);

3 - catalyst (red);

4 - cathode

Proton exchange membrane fuel cell (PEMFC) uses one of the simplest reactions of any fuel cell.

Single cell fuel cell

Let's look at how a fuel cell works. The anode, the negative terminal of the fuel cell, conducts electrons that are freed from hydrogen molecules so that they can be used in the external electrical circuit. To do this, channels are engraved in it, distributing hydrogen evenly over the entire surface of the catalyst. The cathode (positive pole of the fuel cell) has etched channels that distribute oxygen across the surface of the catalyst. It also conducts electrons back from the outer loop (circuit) to the catalyst, where they can combine with hydrogen ions and oxygen to form water. The electrolyte is a proton exchange membrane. This is a special material that is similar to ordinary plastic, but has the ability to allow positively charged ions to pass through and block the passage of electrons.

A catalyst is a special material that facilitates the reaction between oxygen and hydrogen. The catalyst is usually made from platinum powder applied in a very thin layer to carbon paper or cloth. The catalyst must be rough and porous so that its surface can come into maximum contact with hydrogen and oxygen. The platinum-coated side of the catalyst is in front of the proton exchange membrane (PEM).

Hydrogen gas (H2) is supplied to the fuel cell under pressure from the anode. When an H2 molecule comes into contact with platinum on the catalyst, it splits into two parts, two ions (H+) and two electrons (e–). The electrons are conducted through the anode, where they pass through an external loop (circuit) doing useful work (such as driving an electric motor) and return at the cathode side of the fuel cell.

Meanwhile, on the cathode side of the fuel cell, oxygen gas (O 2 ) is forced through the catalyst, where it forms two oxygen atoms. Each of these atoms has a strong negative charge, which attracts two H+ ions across the membrane, where they combine with an oxygen atom and two electrons from the outer circuit to form a water molecule (H 2 O).

This reaction in a single fuel cell produces approximately 0.7 W of power. To raise power to the required level, many individual fuel cells must be combined to form a fuel cell stack.

POM fuel cells operate at relatively low temperatures (around 80°C), meaning they can be quickly brought up to operating temperature and do not require expensive cooling systems. Continuous improvements in the technologies and materials used in these cells have brought their power closer to the point where a battery of such fuel cells, occupying a small part of the trunk of a car, can provide the energy needed to drive the car.

Over the past years, most of the world's leading automobile manufacturers have been investing heavily in the development of vehicle designs that use fuel cells. Many have already demonstrated fuel cell vehicles with satisfactory power and dynamics characteristics, although they were quite high cost.

The improvement of the designs of such cars is very intensive.

Fuel cell vehicle uses a power plant located under the vehicle's floor

The NECAR V is based on a Mercedes-Benz A-class car, with the entire power plant, along with fuel cells, located under the floor of the car. This constructive solution makes it possible to accommodate four passengers and luggage in the car. Here, not hydrogen, but methanol is used as fuel for the car. Methanol, using a reformer (a device that converts methanol into hydrogen), is converted into hydrogen necessary to power the fuel cell. Using a reformer on board a car makes it possible to use almost any hydrocarbons as fuel, which allows you to refuel a fuel cell car using the existing network of gas stations. In theory, fuel cells produce nothing but electricity and water. Converting fuel (gasoline or methanol) into hydrogen needed for a fuel cell somewhat reduces the environmental appeal of such a car.

Honda, which has been involved in fuel cells since 1989, produced a small batch of Honda FCX-V4 vehicles in 2003 with proton exchange membrane fuel cells from Ballard. These fuel cells generate 78 kW of electrical power, and traction electric motors with a power of 60 kW and a torque of 272 Nm are used to drive the drive wheels. A fuel cell car, compared to a traditional car, has a weight of approximately 40% less, which ensures it has excellent dynamics, and the supply of compressed hydrogen allows it to run up to 355 km.

The Honda FCX uses electric energy generated by fuel cells to drive.

The Honda FCX is the world's first fuel cell vehicle to receive government certification in the United States. The car is certified according to ZEV standards - Zero Emission Vehicle (zero pollution vehicle). Honda is not going to sell these cars yet, but is leasing about 30 cars per unit. California and Tokyo, where hydrogen refueling infrastructure already exists.

General Motors' Hy Wire concept vehicle has a fuel cell powertrain

General Motors is conducting extensive research into the development and creation of fuel cell vehicles.

Hy Wire car chassis

The GM Hy Wire concept car was issued 26 patents. The basis of the car is a functional platform 150 mm thick. Inside the platform are hydrogen tanks, a fuel cell powertrain and vehicle control systems using the latest drive-by-wire technologies. The Hy Wire vehicle's chassis is a thin platform that encloses all of the vehicle's major structural elements: hydrogen tanks, fuel cells, batteries, electric motors and control systems. This approach to design makes it possible to change car bodies during operation. The company is also testing prototype Opel fuel cell cars and designing a plant for the production of fuel cells.

Design of a "safe" liquefied hydrogen fuel tank:

1 - filling device;

2 - external tank;

3 - supports;

4 - level sensor;

5 - internal tank;

6 - filling line;

7 - insulation and vacuum;

8 - heater;

9 - mounting box

BMW pays a lot of attention to the problem of using hydrogen as a fuel for cars. Together with Magna Steyer, renowned for its work on the use of liquefied hydrogen in space exploration, BMW has developed a fuel tank for liquefied hydrogen that can be used in cars.

Tests have confirmed the safety of using a liquid hydrogen fuel tank

The company conducted a series of tests for the safety of the structure using standard methods and confirmed its reliability.

In 2002, at the motor show in Frankfurt am Main (Germany), the Mini Cooper Hydrogen, which uses liquefied hydrogen as fuel, was shown. The fuel tank of this car takes up the same space as a regular gas tank. Hydrogen in this car is not used for fuel cells, but as fuel for the internal combustion engine.

The world's first production car with a fuel cell instead of a battery

In 2003, BMW announced the production of the first production car with a fuel cell, the BMW 750 hL. A fuel cell battery is used instead of a traditional battery. This car has a 12-cylinder internal combustion engine running on hydrogen, and the fuel cell serves as an alternative to a conventional battery, allowing the air conditioner and other electrical consumers to operate when the car is parked for long periods without the engine running.

Hydrogen filling is carried out by a robot, the driver is not involved in this process

The same BMW company has also developed robotic refueling dispensers that provide fast and safe refueling of cars with liquefied hydrogen.

Appearance in last years The large number of developments aimed at creating cars using alternative fuels and alternative powertrains suggests that internal combustion engines, which have dominated automobiles for the past century, will eventually give way to cleaner, more efficient and quieter designs. Their widespread adoption is currently constrained not by technical, but rather by economic and social problems. For their widespread use, it is necessary to create a certain infrastructure for the development of the production of alternative fuels, the creation and distribution of new gas stations and to overcome a number of psychological barriers. The use of hydrogen as a vehicle fuel will require addressing issues of storage, delivery and distribution, with serious safety measures in place.

Hydrogen is theoretically available in unlimited quantities, but its production is very energy intensive. In addition, to convert cars to run on hydrogen fuel, it is necessary to make two big changes to the power system: first, switching its operation from gasoline to methanol, and then, over a period of time, to hydrogen. It will be some time before this issue is resolved.

Fuel cell ( Fuel Cell) is a device that converts chemical energy into electrical energy. It is similar in principle to a conventional battery, but differs in that its operation requires a constant supply of substances from the outside for the electrochemical reaction to occur. Hydrogen and oxygen are supplied to the fuel cells, and the output is electricity, water and heat. Their advantages include environmental friendliness, reliability, durability and ease of operation. Unlike conventional batteries, electrochemical converters can operate virtually indefinitely as long as fuel is supplied. They don't have to be charged for hours until they're fully charged. Moreover, the cells themselves can charge the battery while the car is parked with the engine turned off.

The most widely used fuel cells in hydrogen vehicles are proton membrane fuel cells (PEMFCs) and solid oxide fuel cells (SOFCs).

A proton exchange membrane fuel cell works as follows. Between the anode and cathode there is a special membrane and a platinum-coated catalyst. Hydrogen is supplied to the anode, and oxygen (for example, from air) is supplied to the cathode. At the anode, hydrogen is decomposed into protons and electrons with the help of a catalyst. Hydrogen protons pass through the membrane and reach the cathode, and electrons are transferred to the external circuit (the membrane does not allow them to pass through). The potential difference thus obtained leads to the generation of electric current. On the cathode side, hydrogen protons are oxidized by oxygen. As a result, water vapor appears, which is the main element of car exhaust gases. Possessing high efficiency, PEM cells have one significant drawback - their operation requires pure hydrogen, the storage of which is a rather serious problem.

If such a catalyst is found that replaces expensive platinum in these cells, then a cheap fuel cell for generating electricity will immediately be created, which means the world will get rid of oil dependence.

Solid Oxide Cells

Solid oxide SOFC cells are much less demanding on fuel purity. In addition, thanks to the use of a POX reformer (Partial Oxidation), such cells can consume regular gasoline as fuel. The process of converting gasoline directly into electricity is as follows. In a special device - a reformer, at a temperature of about 800 ° C, gasoline evaporates and decomposes into its constituent elements.

This releases hydrogen and carbon dioxide. Further, also under the influence of temperature and using SOFC directly (consisting of a porous ceramic material based on zirconium oxide), hydrogen is oxidized by oxygen in the air. After obtaining hydrogen from gasoline, the process continues according to the scenario described above, with only one difference: the SOFC fuel cell, unlike devices operating on hydrogen, is less sensitive to impurities in the original fuel. So the quality of gasoline should not affect the performance of the fuel cell.

The high operating temperature of SOFC (650–800 degrees) is a significant drawback; the warm-up process takes about 20 minutes. But excess heat is not a problem, since it is completely removed by the remaining air and exhaust gases produced by the reformer and the fuel cell itself. This allows the SOFC system to be integrated into a vehicle as a separate device in a thermally insulated housing.

The modular structure allows you to achieve the required voltage by connecting a set of standard cells in series. And, perhaps most importantly from the point of view of the implementation of such devices, SOFC does not contain very expensive platinum-based electrodes. It is the high cost of these elements that is one of the obstacles in the development and dissemination of PEMFC technology.

Types of fuel cells

Currently, there are the following types of fuel cells:

- A.F.C.– Alkaline Fuel Cell (alkaline fuel cell);

- PAFC– Phosphoric Acid Fuel Cell (phosphoric acid fuel cell);

- PEMFC– Proton Exchange Membrane Fuel Cell (fuel cell with a proton exchange membrane);

- DMFC– Direct Methanol Fuel Cell (fuel cell with direct breakdown of methanol);

- MCFC– Molten Carbonate Fuel Cell (fuel cell of molten carbonate);

- SOFC– Solid Oxide Fuel Cell (solid oxide fuel cell).

Fuel cells (electrochemical generators) represent a very efficient, durable, reliable and environmentally friendly method of generating energy. Initially, they were used only in the space industry, but today electrochemical generators are increasingly used in various fields: power supplies for mobile phones and laptops, vehicle engines, autonomous power sources for buildings, and stationary power plants. Some of these devices operate as laboratory prototypes, while others are used for demonstration purposes or are undergoing pre-production testing. However, many models are already used in commercial projects and are mass-produced.

Device

Fuel cells are electrochemical devices capable of providing a high conversion rate of existing chemical energy into electrical energy.

The fuel cell device includes three main parts:

- Power generation section;

- CPU;

- Voltage transformer.

The main part of the fuel cell is the power generation section, which is a battery made of individual fuel cells. A platinum catalyst is included in the structure of the fuel cell electrodes. Using these cells, a constant electric current is created.

One of these devices has the following characteristics: at a voltage of 155 volts, 1400 amperes are produced. The battery dimensions are 0.9 m in width and height, and 2.9 m in length. The electrochemical process in it is carried out at a temperature of 177 °C, which requires heating of the battery at the time of start-up, as well as heat removal during its operation. For this purpose, a separate water circuit is included in the fuel cell, and the battery is equipped with special cooling plates.

The fuel process converts natural gas into hydrogen, which is required for an electrochemical reaction. The main element of the fuel processor is the reformer. In it, natural gas (or other hydrogen-containing fuel) interacts at high pressure and high temperature (about 900 ° C) with water vapor under the action of a nickel catalyst.

To maintain the required temperature of the reformer there is a burner. The steam required for reforming is created from the condensate. An unstable direct current is generated in the fuel cell battery and a voltage converter is used to convert it.

Also in the voltage converter block there are:

- Control devices.

- Safety interlock circuits that shut down the fuel cell during various faults.

Operating principle

The simplest proton exchange membrane cell consists of a polymer membrane that is located between the anode and cathode, as well as the cathode and anode catalysts. The polymer membrane is used as an electrolyte.

- The proton exchange membrane looks like a thin solid organic compound of small thickness. This membrane works as an electrolyte; in the presence of water, it separates the substance into negatively and positively charged ions.

- Oxidation begins at the anode, and reduction occurs at the cathode. The cathode and anode in a PEM cell are made of porous material; it is a mixture of platinum and carbon particles. Platinum acts as a catalyst, which promotes the dissociation reaction. The cathode and anode are made porous so that oxygen and hydrogen pass through them freely.

- The anode and cathode are located between two metal plates, they supply oxygen and hydrogen to the cathode and anode, and remove electrical energy, heat and water.

- Through channels in the plate, hydrogen molecules enter the anode, where the molecules are decomposed into atoms.

- As a result of chemisorption under the influence of a catalyst, hydrogen atoms are converted into positively charged hydrogen ions H+, that is, protons.

- Protons diffuse to the cathode through the membrane, and a flow of electrons goes to the cathode through a special external electrical circuit. A load is connected to it, that is, a consumer of electrical energy.

- Oxygen, which is supplied to the cathode, upon exposure, enters into a chemical reaction with electrons from the external electrical circuit and hydrogen ions from the proton exchange membrane. As a result of this chemical reaction, water appears.

The chemical reaction that occurs in other types of fuel cells (for example, with an acidic electrolyte in the form of orthophosphoric acid H3PO4) is completely identical to the reaction of a device with a proton exchange membrane.

Kinds

Currently, several types of fuel cells are known, which differ in the composition of the electrolyte used:

- Fuel cells based on orthophosphoric or phosphoric acid (PAFC, Phosphoric Acid Fuel Cells).

- Devices with proton exchange membrane (PEMFC, Proton Exchange Membrane Fuel Cells).

- Solid oxide fuel cells (SOFC, Solid Oxide Fuel Cells).

- Electrochemical generators based on molten carbonate (MCFC, Molten Carbonate Fuel Cells).

Currently, electrochemical generators using PAFC technology have become more widespread.

Application

Today, fuel cells are used in the Space Shuttle, reusable spacecraft. They use 12 W units. They generate all the electricity on the spacecraft. The water that is formed during the electrochemical reaction is used for drinking, including for cooling equipment.

Electrochemical generators were also used to power the Soviet Buran, a reusable spacecraft.

Fuel cells are also used in the civilian sector.

- Stationary installations with a power of 5–250 kW and above. They are used as autonomous sources for heat and power supply to industrial, public and residential buildings, emergency and backup power supplies, and uninterruptible power supplies.

- Portable units with a power of 1–50 kW. They are used for space satellites and ships. Instances are created for golf carts, wheelchairs, railway and freight refrigerators, and road signs.

- Mobile installations with a power of 25–150 kW. They are beginning to be used in military ships and submarines, including cars and other vehicles. Prototypes have already been created by such automotive giants as Renault, Neoplan, Toyota, Volkswagen, Hyundai, Nissan, VAZ, General Motors, Honda, Ford and others.

- Microdevices with a power of 1–500 W. They find application in advanced handheld computers, laptops, consumer electronic devices, mobile phones, and modern military devices.

Peculiarities

- Some of the energy from the chemical reaction in each fuel cell is released as heat. Refrigeration required. In an external circuit, the flow of electrons creates a direct current that is used to do work. Stopping the movement of hydrogen ions or opening the external circuit leads to the stop of the chemical reaction.

- The amount of electricity that fuel cells create is determined by gas pressure, temperature, geometric dimensions, and type of fuel cell. To increase the amount of electricity produced by the reaction, fuel cells can be made larger, but in practice several cells are used, which are combined into batteries.

- The chemical process in some types of fuel cells can be reversed. That is, when a potential difference is applied to the electrodes, water can be decomposed into oxygen and hydrogen, which will be collected on the porous electrodes. When the load is turned on, such a fuel cell will generate electrical energy.

Prospects

Currently, electrochemical generators require large initial costs to be used as the main source of energy. With the introduction of more stable membranes with high conductivity, efficient and cheap catalysts, and alternative sources of hydrogen, fuel cells will become highly economically attractive and will be implemented everywhere.

- Cars will run on fuel cells; there will be no internal combustion engines at all. Water or solid-state hydrogen will be used as an energy source. Refueling will be simple and safe, and driving will be environmentally friendly - only water vapor will be produced.

- All buildings will have their own portable fuel cell power generators.

- Electrochemical generators will replace all batteries and will be installed in any electronics and household appliances.

Advantages and disadvantages

Each type of fuel cell has its own disadvantages and advantages. Some require high quality fuel, others have complex design, need high operating temperature.

In general, the following advantages of fuel cells can be noted:

- environmental safety;

- electrochemical generators do not need to be recharged;

- electrochemical generators can create energy constantly, they do not care about external conditions;

- flexibility in scale and portability.

Among the disadvantages are:

- technical difficulties with fuel storage and transportation;

- imperfect elements of the device: catalysts, membranes, and so on.

I insert the filler hose fitting into the fuel filler neck and turn it half a turn to seal the connection. A click of the toggle switch - and the blinking LED on the gas pump with a huge inscription h3 indicates that refueling has started. A minute - and the tank is full, you can go!

Elegant body contours, ultra-low suspension, low-profile slicks give off a real racing breed. Through the transparent cover, an intricate network of pipelines and cables is visible. I've already seen a similar solution somewhere... Oh yes, on the Audi R8 the engine is also visible through the rear window. But on Audi it is traditional gasoline, and this car runs on hydrogen. Like the BMW Hydrogen 7, but unlike the latter, there is no internal combustion engine. The only moving parts are the steering gear and the electric motor rotor. And the energy for it is provided by a fuel cell. This car was produced by the Singaporean company Horizon Fuel Cell Technologies, specializing in the development and production of fuel cells. In 2009, the British company Riversimple already introduced an urban hydrogen car powered by Horizon Fuel Cell Technologies fuel cells. It was developed in collaboration with the Universities of Oxford and Cranfield. But Horizon H-racer 2.0 is a solo development.

The fuel cell consists of two porous electrodes coated with a layer of catalyst and separated by a proton exchange membrane. Hydrogen at the anode catalyst is converted into protons and electrons, which travel through the anode and an external electrical circuit to the cathode, where hydrogen and oxygen recombine to form water.

"Go!" - in Gagarin style he nudges me with his elbow Chief Editor. But not so fast: first you need to “warm up” the fuel cell at part load. I switch the toggle switch to “warm up” mode and wait for the allotted time. Then, just in case, I top up the tank until it’s full. Now let's go: the car, the engine humming smoothly, moves forward. The dynamics are impressive, although, by the way, what else can you expect from an electric car - the torque is constant at any speed. Although not for long - a full tank of hydrogen lasts only a few minutes (Horizon promises to release a new version in the near future, in which hydrogen is not stored as a gas under pressure, but is retained by a porous material in the adsorber). And, frankly speaking, it is not very controlled - there are only two buttons on the remote control. But in any case, it’s a pity that this is only a radio-controlled toy, which cost us $150. We wouldn't mind taking a ride in a real fuel cell car. power plant.

The tank, an elastic rubber container inside a rigid casing, stretches when refueling and works as a fuel pump, “squeezing” hydrogen into the fuel cell. In order not to “overfill” the tank, one of the fittings is connected with a plastic tube to the emergency pressure relief valve.

Gas station

Do it yourself

The Horizon H-racer 2.0 machine is supplied as a kit for large-scale assembly (do-it-yourself type), you can buy it, for example, on Amazon. However, assembling it is not difficult - just put the fuel cell in place and secure it with screws, connect the hoses to the hydrogen tank, fuel cell, filler neck and emergency valve, and all that remains is to put the upper part of the body in place, not forgetting the front and rear bumpers. The kit includes a filling station that produces hydrogen by electrolysis of water. It is powered by two AA batteries, and if you want the energy to be completely “clean”, by solar panels (they are also included in the kit).

www.popmech.ru

How to make a fuel cell with your own hands?

Of course, the simplest solution to the problem of ensuring the constant operation of fuel-free systems is to purchase a ready-made secondary energy source on a hydraulic or any other basis, but in this case it will certainly not be possible to avoid additional costs, and in this process it is quite difficult to consider any idea for flight of creative thought. In addition, making a fuel cell with your own hands is not at all as difficult as you might think at first glance, and even the most inexperienced craftsman can cope with the task if desired. In addition, a more than pleasant bonus will be the low cost of creating this element, because despite all its benefits and importance, you can absolutely easily make do with the means you already have at hand.

In this case, the only nuance that must be taken into account before completing the task is that you can make an extremely low-power device with your own hands, and the implementation of more advanced and complex installations should still be left to qualified specialists. As for the order of work and the sequence of actions, the first step is to complete the body, for which it is best to use thick-walled plexiglass (at least 5 centimeters). For gluing the walls of the case and installing internal partitions, for which it is best to use thinner plexiglass (3 millimeters is enough), ideally use two-composite glue, although if you really want, you can do high-quality soldering yourself, using the following proportions: per 100 grams of chloroform - 6 grams shavings from the same plexiglass.

In this case, the process must be carried out exclusively under a hood. In order to equip the case with the so-called drain system, it is necessary to carefully drill a through hole in its front wall, the diameter of which will exactly match the dimensions of the rubber plug, which serves as a kind of gasket between the case and the glass drain tube. As for the size of the tube itself, ideally its width should be five to six millimeters, although it all depends on the type of structure being designed. It is more likely to say that the old gas mask listed in the list of necessary elements for making a fuel cell will cause some surprise among potential readers of this article. Meanwhile, the entire benefit of this device lies in the activated carbon located in the compartments of its respirator, which can later be used as electrodes.

Since we are talking about a powdery consistency, to improve the design you will need nylon stockings, from which you can easily make a bag and put the coal in it, otherwise it will simply spill out of the hole. As for the distribution function, the concentration of fuel occurs in the first chamber, while the oxygen necessary for the normal functioning of the fuel cell, on the contrary, will circulate in the last, fifth compartment. The electrolyte itself, located between the electrodes, should be soaked in a special solution (gasoline with paraffin in a ratio of 125 to 2 milliliters), and this must be done before placing the air electrolyte in the fourth compartment. To ensure proper conductivity, copper plates with pre-soldered wires are laid on top of the coal, through which electricity will be transmitted from the electrodes.

This design stage can be safely considered the final stage, after which the finished device is charged, for which an electrolyte will be needed. To prepare it, you need to mix in equal parts ethyl alcohol with distilled water and begin gradually introducing caustic potassium at the rate of 70 grams per glass of liquid. Carrying out the first test of the manufactured device consists of simultaneously filling the first (fuel liquid) and third (electrolyte made of ethyl alcohol and caustic potassium) containers of the plexiglass housing.

uznay-kak.ru

Hydrogen fuel cells | LAVENT

I have long wanted to tell you about another direction of the Alfaintek company. This is the development, sale and service of hydrogen fuel cells. I would like to immediately explain the situation with these fuel cells in Russia.

Due to the fairly high cost and the complete lack of hydrogen stations for charging these fuel cells, their sale in Russia is not expected. Nevertheless, in Europe, especially in Finland, these fuel cells are gaining popularity every year. What's the secret? Let's get a look.  This device is environmentally friendly, easy to use and effective. It comes to the aid of a person where he needs electrical energy. You can take it with you on the road, on a hike, or use it in your country house or apartment as an autonomous source of electricity.

This device is environmentally friendly, easy to use and effective. It comes to the aid of a person where he needs electrical energy. You can take it with you on the road, on a hike, or use it in your country house or apartment as an autonomous source of electricity.

Electricity in a fuel cell is generated by a chemical reaction of hydrogen from the tank with metal hydride and oxygen from the air. The cylinder is not explosive and can be stored in your closet for years, waiting in the wings. This is perhaps one of the main advantages of this hydrogen storage technology. It is the storage of hydrogen that is one of the main problems in the development of hydrogen fuel. Unique new lightweight fuel cells that convert hydrogen into conventional electricity safely, quietly and emission-free.

This type of electricity can be used in places where there is no central electricity, or as an emergency power source.

Unlike conventional batteries, which need to be charged and disconnected from the electrical consumer during the charging process, a fuel cell works as a “smart” device. This technology provides uninterrupted power throughout the entire period of use thanks to the unique power saving function when changing the fuel container, which allows the user to never turn off the consumer. In a closed case, fuel cells can be stored for several years without losing the volume of hydrogen and reducing their power.

The fuel cell is intended for scientists and researchers, law enforcement agencies, rescue workers, ship and marina owners, and anyone else who needs reliable source food in case of emergency.  You can get 12 volts or 220 volts and then you will have enough energy to run your TV, stereo, refrigerator, coffee maker, kettle, vacuum cleaner, drill, microstove and other electrical appliances.

You can get 12 volts or 220 volts and then you will have enough energy to run your TV, stereo, refrigerator, coffee maker, kettle, vacuum cleaner, drill, microstove and other electrical appliances.

Hydrocell fuel cells can be sold as a single unit or in batteries of 2-4 cells. Two or four elements can be combined to either increase power or increase amperage.

OPERATING TIME OF HOUSEHOLD APPLIANCES WITH FUEL CELLS

| Electrical appliances | Operating time per day (min.) | Required power per day (Wh) | Operating time with fuel cells |

|||

| Electric kettle | ||||||

| Coffee maker | ||||||

| Microslab | ||||||

| TV | ||||||

| 1 light bulb 60W | ||||||

| 1 light bulb 75W | ||||||

| 3 bulbs 60W | ||||||

| Computer laptop | ||||||

| Fridge | ||||||

| Energy saving lamp | ||||||

* - continuous operation

Fuel cells are fully charged at special hydrogen stations. But what if you travel far from them and there is no way to recharge? Especially for such cases, Alfaintek specialists have developed cylinders for storing hydrogen, with which fuel cells will work much longer.

Two types of cylinders are available: NS-MN200 and NS-MN1200. The assembled NS-MN200 is slightly larger than a Coca-Cola can, it holds 230 liters of hydrogen, which corresponds to 40Ah (12V), and weighs only 2.5 kg .The NS-MN1200 metal hydride cylinder holds 1200 liters of hydrogen, which corresponds to 220Ah (12V). The weight of the cylinder is 11 kg.

The metal hydride technique is a safe and easy way to store, transport and use hydrogen. When stored as a metal hydride, hydrogen is in the form chemical compound, and not in gaseous form. This method makes it possible to obtain a sufficiently high energy density. The advantage of using metal hydride is that the pressure inside the cylinder is only 2-4 bar. The cylinder is not explosive and can be stored for years without reducing the volume of the substance. Since the hydrogen is stored as a metal hydride, the purity of the hydrogen obtained from the cylinder is very high at 99.999%. Metal hydride hydrogen storage cylinders can be used not only with HC 100,200,400 fuel cells, but also in other cases where pure hydrogen is needed. The cylinders can be easily connected to a fuel cell or other device using a quick-connect connector and flexible hose.

It is a pity that these fuel cells are not sold in Russia. But among our population there are so many people who need them. Well, we'll wait and see, and you'll see, we'll have some. In the meantime, we will buy energy-saving light bulbs imposed by the state.

P.S. It looks like the topic has finally faded into oblivion. So many years after this article was written, nothing has come of it. Maybe I’m not looking everywhere, of course, but what catches my eye is not at all pleasing. The technology and idea are good, but they haven’t found any development yet.

lavent.ru

The fuel cell is a future that starts today!

The beginning of the 21st century considers ecology as one of the most important global challenges. And the first thing that should be paid attention to in the current conditions is the search and use of alternative energy sources. They are the ones who are able to prevent pollution of our environment, as well as completely abandon the continuously rising prices of hydrocarbon-based fuels.

Already today, energy sources such as solar cells and wind turbines have found application. But, unfortunately, their disadvantage is associated with dependence on the weather, as well as on the season and time of day. For this reason, their use in astronautics, aircraft and automotive industries is gradually being abandoned, and for stationary use they are equipped with secondary power sources - batteries.

Already today, energy sources such as solar cells and wind turbines have found application. But, unfortunately, their disadvantage is associated with dependence on the weather, as well as on the season and time of day. For this reason, their use in astronautics, aircraft and automotive industries is gradually being abandoned, and for stationary use they are equipped with secondary power sources - batteries.

However, the best solution is a fuel cell, since it does not require constant energy recharging. This is a device that is capable of processing and converting various types of fuel (gasoline, alcohol, hydrogen, etc.) directly into electrical energy.

A fuel cell works on the following principle: fuel is supplied from the outside, which is oxidized by oxygen, and the energy released is converted into electricity. This principle of operation ensures almost eternal operation.

Since the end of the 19th century, scientists have studied the fuel cell itself and constantly developed new modifications of it. So, today, depending on operating conditions, there are alkaline or alkaline (AFC), direct borohydrate (DBFC), electro-galvanic (EGFC), direct methanol (DMFC), zinc-air (ZAFC), microbial (MFC), models on formic acid(DFAFC) and metal hydrides (MHFC).

Since the end of the 19th century, scientists have studied the fuel cell itself and constantly developed new modifications of it. So, today, depending on operating conditions, there are alkaline or alkaline (AFC), direct borohydrate (DBFC), electro-galvanic (EGFC), direct methanol (DMFC), zinc-air (ZAFC), microbial (MFC), models on formic acid(DFAFC) and metal hydrides (MHFC).

One of the most promising is the hydrogen fuel cell. The use of hydrogen in power plants is accompanied by a significant release of energy, and the exhaust from such a device is pure water vapor or drinking water, which do not pose any threat to the environment.

The successful testing of fuel cells of this type on spacecraft has recently aroused considerable interest among manufacturers of electronics and various equipment. Thus, the PolyFuel company presented a miniature hydrogen fuel cell for laptops. But the too high cost of such a device and the difficulties in unhindered refueling limit its industrial production and wide distribution. Honda has also been producing automotive fuel cells for over 10 years. However, this type of transport does not go on sale, but only for the official use of company employees. The cars are under the supervision of engineers.

The successful testing of fuel cells of this type on spacecraft has recently aroused considerable interest among manufacturers of electronics and various equipment. Thus, the PolyFuel company presented a miniature hydrogen fuel cell for laptops. But the too high cost of such a device and the difficulties in unhindered refueling limit its industrial production and wide distribution. Honda has also been producing automotive fuel cells for over 10 years. However, this type of transport does not go on sale, but only for the official use of company employees. The cars are under the supervision of engineers.

Many people wonder whether it is possible to assemble a fuel cell with their own hands. After all, a significant advantage of a homemade device will be a minor investment, in contrast to an industrial model. For the miniature model, you will need 30 cm of platinum-coated nickel wire, a small piece of plastic or wood, a 9-volt battery clip and the battery itself, clear adhesive tape, a glass of water and a voltmeter. Such a device will allow you to see and understand the essence of the work, but, of course, it will not be possible to generate electricity for the car.

fb.ru

Hydrogen fuel cells: a little history | Hydrogen

In our time, the problem of the shortage of traditional energy resources and the deterioration of the planet’s ecology as a whole due to their use is particularly acute. That is why, recently, significant financial resources and intellectual resources have been spent on the development of potentially promising substitutes for hydrocarbon fuels. Hydrogen may become such a substitute in the very near future, since its use in power plants is accompanied by the release of a large amount of energy, and the exhaust is water vapor, that is, it does not pose a danger to the environment.

Despite some technical difficulties that still exist in the implementation of hydrogen-based fuel cells, many car manufacturers have appreciated the promise of the technology and are already actively developing prototypes of production cars capable of using hydrogen as the main fuel. Back in two thousand and eleven, Daimler AG presented conceptual Mercedes-Benz models with hydrogen power plants. In addition, the Korean company Hyndayi has officially announced that it no longer intends to develop electric cars, but will concentrate all its efforts on developing an affordable hydrogen car.

Despite the fact that the very idea of using hydrogen as a fuel is not wild for many, most have no idea how fuel cells that use hydrogen work and what is so remarkable about them.